Semiconductor manufacturing is a complex process involving the creation of integrated circuits and electronic devices․ It requires precision‚ advanced techniques‚ and strict quality control to ensure reliability and performance․

1․1 Overview of the Semiconductor Industry

The semiconductor industry is a global sector driving technological advancements‚ producing integrated circuits‚ and enabling modern electronics․ It involves complex manufacturing processes to create microprocessors‚ memory chips‚ and specialized sensors․ The industry is characterized by continuous innovation‚ high demand‚ and precise quality control‚ making it a cornerstone of the digital economy and a key enabler of technological progress worldwide․

1․2 Importance of Semiconductor Manufacturing

Semiconductor manufacturing is foundational to modern electronics‚ enabling advancements in computing‚ communication‚ and innovation․ It powers devices from smartphones to medical equipment‚ driving technological progress․ The industry’s precision and scalability ensure reliable performance‚ fostering economic growth and shaping global connectivity․ Its impact spans industries‚ making it indispensable for future advancements and societal development․

Wafer Fabrication Process

Wafer fabrication is a sophisticated process creating integrated circuits on silicon wafers․ It involves crystal growth‚ oxidation‚ diffusion‚ and photolithography‚ requiring precision for reliable semiconductor devices․

2․1 Crystal Growth and Wafer Preparation

Crystal growth involves creating high-purity silicon ingots using the Czochralski process․ Wafers are sliced from these ingots‚ then polished and cleaned․ Doping introduces impurities to alter conductivity‚ preparing the wafer for subsequent fabrication steps․

2․2 Oxidation and Epitaxy

Oxidation forms a silicon dioxide layer on the wafer surface‚ enhancing insulation and transistor performance․ Epitaxy involves growing a crystalline layer‚ ensuring uniform structure and improved electrical properties․ These processes are critical for creating the foundation of modern semiconductor devices․

2․3 Diffusion and Ion Implantation

Diffusion introduces impurities into the wafer‚ creating regions with varying electrical properties․ Ion implantation precisely dopes areas by accelerating ions‚ ensuring controlled and uniform distribution․ Both processes are essential for forming transistors and achieving desired electrical characteristics in semiconductor devices․

Photolithography

Photolithography is a critical step in semiconductor manufacturing‚ using light to transfer patterns onto wafers․ It ensures precise circuit layouts‚ enabling the creation of high-density microchips․

3․1 Principles of Photolithography

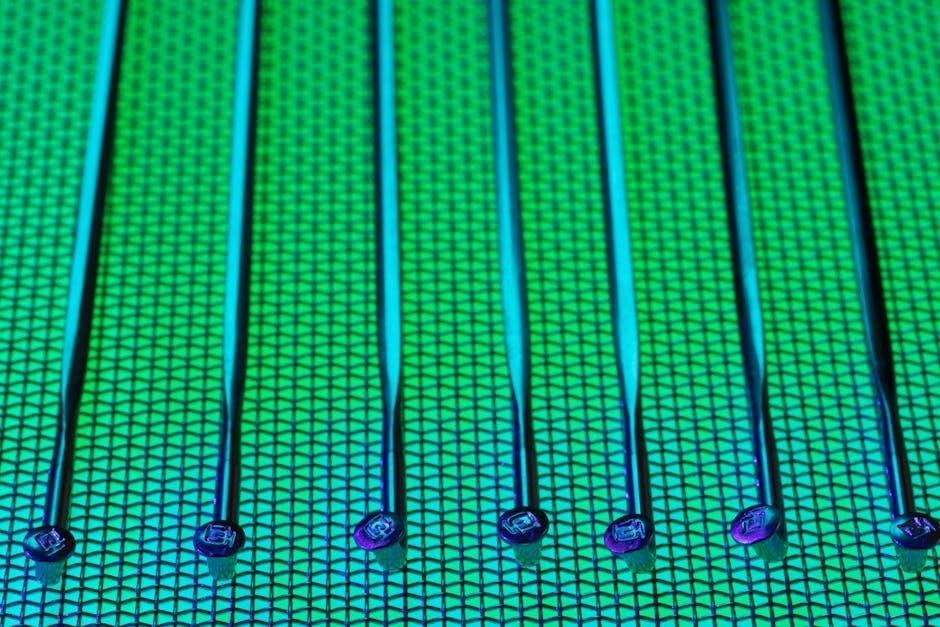

Photolithography involves using ultraviolet light to transfer patterns from a photomask onto a photosensitive material on a wafer․ The process includes coating the wafer with photoresist‚ exposing it to light through a mask‚ and developing the resist to create a pattern․ This technique is essential for achieving the tiny‚ complex structures required in modern semiconductors‚ ensuring high precision and consistency․

3․2 Photoresist Application and Exposure

Photoresist application involves coating the wafer with a light-sensitive material․ Exposure uses ultraviolet light to project patterns from a photomask onto the photoresist․ The resist either hardens or softens depending on the light’s wavelength․ Proper alignment and controlled environments ensure accurate pattern transfer․ This step is critical for defining circuit structures‚ requiring precise focus and intensity to achieve high-quality results․

Etching Processes

Etching processes are essential for creating precise patterns on wafers by selectively removing materials․ They play a crucial role in defining the semiconductor’s functionality and structure;

4․1 Dry Etching Techniques

Dry etching uses plasma or chemical reactions to remove materials without liquids․ Techniques include reactive ion etching (RIE) and inductively coupled plasma (ICP) etching‚ offering high precision and anisotropic profiles․

4․2 Wet Etching Techniques

Wet etching involves chemical solutions to dissolve and remove materials․ It’s often isotropic‚ offering simplicity and cost-effectiveness․ Common acids and bases are used‚ with applications in substrate preparation and pattern transfer‚ ensuring uniformity and compatibility with various semiconductor materials․

Deposition Processes

Deposition is a critical step in semiconductor manufacturing‚ creating thin films on wafers․ Techniques like CVD and PVD ensure precise material properties‚ enhancing device performance and reliability․

5․1 Chemical Vapor Deposition (CVD)

Chemical Vapor Deposition (CVD) is a widely used technique in semiconductor manufacturing․ It involves depositing thin films on a substrate through chemical reactions in a vapor phase․ CVD is essential for creating insulating layers‚ conductive materials‚ and protective coatings․ The process offers high uniformity and scalability‚ making it crucial for modern semiconductor production․

5․2 Physical Vapor Deposition (PVD)

Physical Vapor Deposition (PVD) is a thin-film deposition technique used in semiconductor manufacturing․ Unlike CVD‚ PVD involves the evaporation of material in a vacuum and its condensation on the substrate․ It is commonly used for metallization and creating conductive layers․ PVD offers high purity and controlled film thickness‚ making it ideal for advanced semiconductor applications and interconnects․

Metallization

Metallization is a critical step in semiconductor manufacturing‚ enabling the creation of interconnections between devices․ It involves depositing conductive materials like aluminum and copper onto the wafer’s surface;

6․1 Materials Used in Metallization

Metallization utilizes conductive materials like aluminum‚ copper‚ and tungsten to create interconnections․ Copper is preferred for its high conductivity‚ while tungsten is used for vias․ Barrier layers‚ such as titanium nitride‚ prevent diffusion and ensure adhesion․ These materials are applied through techniques like sputtering or chemical vapor deposition (CVD)‚ enabling reliable and efficient electrical pathways in semiconductor devices․

6․2 Metallization Techniques

Metallization techniques involve depositing conductive materials to form interconnections․ Sputtering and chemical vapor deposition (CVD) are common methods for applying metals like copper and aluminum․ Physical vapor deposition (PVD) is also used for thin‚ uniform layers․ These techniques ensure high conductivity‚ reliability‚ and compatibility with semiconductor devices‚ enabling efficient signal transmission and device functionality․

Packaging and Assembly

Packaging and assembly involve protecting the semiconductor die and connecting it to external circuits․ Key steps include wafer dicing‚ packaging‚ wire bonding‚ and encapsulation to ensure reliability and functionality․

7․1 Wafer Dicing and Packaging

Wafer dicing involves cutting the silicon wafer into individual dice or chips using precise diamond-edged saws․ Packaging then encapsulates the die‚ protecting it from environmental stressors and enabling electrical connections․ This step is crucial for ensuring device reliability‚ durability‚ and functionality in final applications․ Advanced packaging techniques optimize performance and minimize size for modern electronics․

7․2 Wire Bonding and Encapsulation

Wire bonding connects the semiconductor die to the package using thin metal wires‚ ensuring electrical connectivity․ Encapsulation follows‚ sealing the die in a protective material like epoxy or mold compound to prevent contamination and physical damage․ This step is vital for safeguarding the chip during handling and use‚ ensuring long-term reliability and performance in various applications․

Process Control and Monitoring

Process control ensures high-quality semiconductor production by monitoring critical parameters and automating tasks to minimize human error․ Advanced systems track gas levels and material conditions to prevent contamination․

8․1 Role of Automation in Semiconductor Manufacturing

Automation plays a pivotal role in semiconductor manufacturing by minimizing human intervention‚ enhancing precision‚ and ensuring consistency across fabrication processes․ Automated systems handle tasks such as material handling‚ process monitoring‚ and quality control‚ significantly reducing errors and improving overall efficiency in high-volume production environments․ This enables faster production cycles and higher yield rates․

8․2 Gas Monitoring and Contamination Control

Gas monitoring is critical in semiconductor manufacturing to prevent contamination and ensure optimal process conditions․ Advanced systems track gases from various sources‚ maintaining purity and preventing defects․ Contamination control measures include filtration‚ ventilation‚ and real-time monitoring‚ ensuring high-quality output and process reliability in cleanroom environments․ This is vital for achieving consistent and defect-free semiconductor production․

Challenges in Semiconductor Manufacturing

Semiconductor manufacturing faces challenges like increasing complexity‚ contamination risks‚ and the need for precise process control․ Advanced monitoring systems are essential to address these issues effectively․

9․1 Common Errors and Mitigation Strategies

Common errors in semiconductor manufacturing include contamination‚ thermal budget deviations‚ and pattern defects․ Mitigation strategies involve advanced automation‚ real-time monitoring systems‚ and robust quality control processes to minimize defects and ensure process consistency․ Proper training and adherence to protocols further enhance error prevention‚ maintaining high yields and reliability in production․

9․2 Complexity of Modern Semiconductor Processes

Modern semiconductor processes are highly intricate due to shrinking geometries‚ multi-layered structures‚ and advanced materials like SiC․ These processes require precise control over temperatures‚ pressures‚ and chemical deposition․ The integration of wide bandgap materials and 3D architectures further complicates manufacturing‚ necessitating cutting-edge tools and sophisticated process monitoring to achieve desired performance and reliability․

Advanced Manufacturing Techniques

Advanced techniques like atomic layer deposition and plasma etching enable precise control‚ while wide bandgap materials and automation enhance performance and efficiency in semiconductor production․

10․1 Silicon Carbide (SiC) Semiconductor Manufacturing

Silicon Carbide (SiC) manufacturing involves producing high-performance semiconductors for power electronics․ SiC’s wide bandgap enables devices to operate at higher temperatures‚ voltages‚ and frequencies․ The process includes substrate preparation‚ epitaxial growth‚ and device fabrication․ Techniques like chemical vapor deposition (CVD) and physical vapor deposition (PVD) are used to deposit thin films․ SiC devices are crucial for applications in renewable energy and electric vehicles․

10․2 Wide Bandgap Material Processing

Wide bandgap materials like SiC and GaN are processed using advanced techniques to create high-power‚ high-frequency devices․ These materials offer superior thermal conductivity and breakdown voltage․ Processing involves epitaxial growth‚ doping‚ and surface passivation․ Techniques like CVD and PVD are employed to ensure material quality․ These materials are essential for next-gen applications in power electronics‚ 5G‚ and renewable energy systems․

Testing and Quality Assurance

Testing and quality assurance are critical in ensuring semiconductor reliability․ Parametric testing verifies device performance‚ while final testing identifies failures‚ ensuring high-quality products for market deployment․

11․1 Parametric Testing

Parametric testing evaluates key electrical parameters of semiconductor devices‚ ensuring they meet specifications․ This includes measuring voltage‚ current‚ and resistance during manufacturing․ It identifies deviations early‚ preventing defects and ensuring consistency across production batches․ Automated systems enhance accuracy‚ while data analytics optimize yield and reliability․ This step is vital for maintaining high-quality semiconductor products․

11․2 Final Testing and Device Failure Analysis

Final testing ensures semiconductor devices function as intended after packaging․ This stage verifies electrical performance and reliability․ Device failure analysis identifies defects‚ using techniques like electron microscopy and physical failure analysis․ Insights gained improve manufacturing processes and yield‚ ensuring high-quality products․ This critical step guarantees devices meet specifications and customer expectations before market release․

Environmental and Safety Considerations

Semiconductor manufacturing requires strict environmental and safety protocols to handle hazardous materials and maintain cleanroom conditions․ Ensuring worker safety and minimizing ecological impact are critical industry priorities․

12․1 Cleanroom Environments

Cleanrooms in semiconductor manufacturing are controlled environments with minimal airborne particles‚ ensuring high-quality production․ These spaces use advanced air filtration systems to maintain optimal conditions‚ critical for preventing contamination during wafer fabrication and other sensitive processes․ Strict protocols govern personnel attire and movement to uphold cleanliness standards essential for reliable semiconductor device manufacturing․

12․2 Handling Hazardous Materials

The handling of hazardous materials in semiconductor manufacturing requires strict safety protocols to protect workers and the environment․ Chemicals used in processes like etching and doping pose significant risks․ Proper personal protective equipment‚ ventilation systems‚ and spill containment measures are essential․ Training and adherence to safety guidelines ensure safe handling and minimize exposure risks during manufacturing operations․

Future Trends in Semiconductor Manufacturing

The future of semiconductor manufacturing emphasizes emerging technologies‚ sustainability‚ and advanced materials like Silicon Carbide and Wide Bandgap materials to enhance performance and reduce environmental impact․

13․1 Emerging Technologies and Innovations

Emerging technologies in semiconductor manufacturing include 3D stacked processors‚ neuromorphic computing‚ and advanced node scaling (2nm‚ 1nm)․ These innovations aim to enhance performance‚ reduce power consumption‚ and enable next-generation applications like AI and IoT․ Sustainability efforts also focus on green manufacturing practices and resource efficiency to meet global demand while minimizing environmental impact․

13;2 Sustainability in Semiconductor Production

Sustainability in semiconductor production focuses on reducing environmental impact through green manufacturing practices․ Key areas include water conservation‚ energy efficiency‚ and waste reduction․ Advanced recycling technologies and renewable energy integration are being adopted to minimize carbon emissions․ Sustainable practices ensure long-term resource availability while maintaining high performance standards‚ addressing global environmental challenges without compromising technological advancement․