The Lisle 59000 Valve Guide Installation Tool is a specialized device designed to simplify and precision-install valve guides in engine cylinder heads‚ ensuring proper alignment and seating for optimal engine performance and durability.

Overview of the Tool and Its Purpose

The Lisle 59000 Valve Guide Installation Tool is a specialized instrument designed to facilitate the precise installation of valve guides in engine cylinder heads. Its primary purpose is to ensure accurate alignment and proper seating of valve guides‚ which are critical for maintaining engine performance and preventing damage. The tool is engineered to simplify the process‚ reducing the need for heavy machinery and enabling both professional mechanics and DIY enthusiasts to achieve professional-grade results efficiently.

Importance of Proper Valve Guide Installation

Proper valve guide installation is critical for maintaining engine performance‚ longevity‚ and efficiency. Valve guides play a vital role in supporting the valves and ensuring proper sealing‚ which prevents oil leakage and maintains compression. Improper installation can lead to engine damage‚ increased oil consumption‚ and reduced performance. The Lisle 59000 tool ensures precise alignment and seating‚ minimizing the risk of these issues and promoting optimal engine operation. Accurate installation is essential for reliability and durability‚ making the Lisle tool indispensable for both professionals and DIY enthusiasts.

What Are Valve Guides and Why Are They Critical?

Valve guides are cylindrical components in engine cylinder heads that support the valves‚ ensuring proper alignment and movement. They are critical for maintaining engine efficiency and performance.

Function of Valve Guides in Engine Operation

Valve guides play a critical role in engine operation by ensuring precision alignment and smooth movement of the valves. They maintain proper sealing integrity‚ preventing oil leakage and ensuring efficient combustion. Guides also facilitate thermal management‚ dissipating heat from the valves to the cylinder head. Properly functioning valve guides are essential for maintaining engine performance‚ fuel efficiency‚ and preventing premature wear on valve train components. Their failure can lead to decreased engine efficiency and potential damage to surrounding parts.

Consequences of Worn or Damaged Valve Guides

Worn or damaged valve guides can lead to reduced engine performance‚ increased oil consumption‚ and decreased fuel efficiency. They may cause valve misalignment‚ resulting in poor sealing‚ combustion leaks‚ and premature wear on engine components. Over time‚ this can lead to engine damage‚ costly repairs‚ and potentially complete engine failure if left unaddressed. Proper installation and maintenance of valve guides are essential to prevent these issues and ensure optimal engine operation.

Features and Benefits of the Lisle 59000 Tool

The Lisle 59000 Tool offers an ergonomic design and durable construction‚ ensuring precise valve guide installation. It streamlines the process‚ reducing engine damage risk and enhancing efficiency.

Design and Construction of the Tool

The Lisle 59000 Tool is crafted with high-quality‚ heat-treated steel for durability and precision. Its ergonomic design ensures ease of use‚ while its compact‚ lightweight build allows for efficient handling. The toolset includes components for both guide removal and installation‚ eliminating the need for heavy machinery. Its robust construction ensures consistent performance‚ making it suitable for professional mechanics and DIY enthusiasts alike. The tool’s design focuses on accuracy and ease of operation‚ ensuring proper valve guide alignment and seating.

Advantages Over Other Installation Methods

The Lisle 59000 Tool offers significant advantages‚ including ease of use and precision alignment‚ eliminating the need for heavy machinery. Its compact design allows for efficient handling‚ reducing installation time and effort. The tool ensures accurate seating and alignment of valve guides‚ minimizing the risk of damage. It is ideal for both professional mechanics and DIY enthusiasts‚ providing a cost-effective solution. Additionally‚ the tool supports various engine types‚ making it versatile for different applications. Its durability and reliability further enhance its value.

Safety Considerations and Precautions

Always wear protective gear‚ including gloves and safety glasses‚ when using the Lisle 59000 Tool. Ensure proper tool handling and follow the manufacturer’s instructions to avoid injuries or damage.

Essential Safety Measures During Installation

- Wear protective gloves and safety glasses to prevent injury from debris or tool mishandling.

- Ensure the workspace is clean and well-lit to minimize hazards and ensure clear visibility.

- Follow the manufacturer’s instructions for proper tool usage and installation techniques.

- Secure the cylinder head firmly to prevent movement during the installation process.

- Use proper alignment tools to avoid damaging the valve guides or surrounding components.

Common Mistakes to Avoid

- Incorrect alignment of the tool can damage the cylinder head or valve guide.

- Using excessive force may result in improper seating or tool breakage.

- Not following torque specifications can lead to loose or over-tightened guides.

- Improper cleaning of the cylinder head before installation can cause poor fitment.

- Attempting installation without proper training or experience can lead to costly repairs.

Typical Applications of the Lisle 59000 Tool

The Lisle 59000 tool is primarily used for valve guide installation in engine repair and rebuilding‚ compatible with various engines‚ and ideal for professional mechanics and DIY projects.

Compatible Engine Types and Models

The Lisle 59000 tool is compatible with various domestic and import engines‚ particularly those requiring precise valve guide installation. It works with cast iron and aluminum cylinder heads‚ supporting bronze or steel guides. Ideal for engines like the 2002 Toyota Camry 4-cyl and 2005 Camry‚ it also suits other models needing accurate guide alignment. Its versatility makes it a valuable tool for both professional mechanics and DIY enthusiasts tackling engine repairs and rebuilds;

Use Cases in Professional and DIY Settings

The Lisle 59000 tool is widely used in both professional and DIY settings for precise valve guide installations. Professional mechanics rely on it for its accuracy and efficiency in engine repairs and rebuilds. DIY enthusiasts appreciate its ease of use‚ enabling them to achieve professional-quality results without specialized machinery. Its versatility makes it ideal for small-scale projects and large engine overhauls‚ ensuring proper guide alignment and extending engine lifespan in various applications.

Step-by-Step Installation Guide

Final Thoughts on the Lisle 59000 Tool

The Lisle 59000 tool is excellent for precise valve guide installations. Highly recommended by professionals and DIYers for its effectiveness. Videos and tutorials are available online for guidance.

Preparing the Cylinder Head for Installation

Before using the Lisle 59000 tool‚ ensure the cylinder head is clean and free of debris. Remove old valve guides and inspect the head for damage. Use a drill press to enlarge guide holes if necessary‚ ensuring precise alignment. Apply a thin layer of lubricant to the new guides for smooth installation. Secure the head in a vise to maintain stability during the process. Proper preparation ensures accurate seating and alignment of the valve guides.

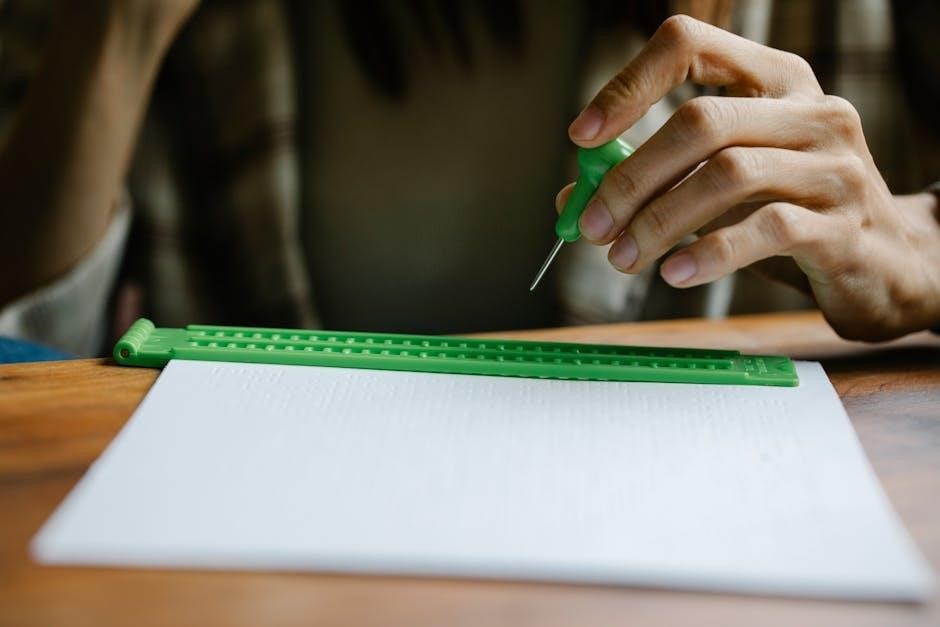

Using the Lisle 59000 Tool Effectively

Align the Lisle 59000 tool with the valve guide hole‚ ensuring proper seating. Gently press the tool into place‚ using the built-in driver to secure the guide. Apply steady‚ even pressure to avoid misalignment. Once seated‚ use the tool’s handle to ensure the guide is fully installed and level. Double-check alignment and fitment before releasing. This method ensures precise installation‚ reducing the risk of damage to the cylinder head or valve guides.

Videos and Online Resources

YouTube features practical demonstrations of the Lisle 59000 tool in action‚ showcasing its use for installing bronze valve guides and shared user experiences.

Recommended Tutorials and Demonstrations

YouTube and automotive forums offer detailed tutorials demonstrating the Lisle 59000 tool in action. These videos provide step-by-step guidance for installing valve guides‚ highlighting proper techniques and common pitfalls to avoid; Many users share their experiences‚ showcasing how the tool simplifies the process of valve guide replacement without requiring heavy machinery. These resources are invaluable for both professional mechanics and DIY enthusiasts looking to achieve precise‚ professional-grade results. They emphasize the tool’s efficiency and reliability in various engine applications.

Community Feedback and Reviews

The Lisle 59000 tool has garnered positive feedback for its effectiveness and ease of use. Many users praise its ability to simplify valve guide installation‚ saving time and effort. However‚ some have noted difficulty in sourcing the tool due to its discontinued status. Forum discussions and YouTube comments highlight its reliability‚ with enthusiasts recommending it for precise installations. While availability is a concern‚ the tool remains a trusted choice for achieving professional results in engine repairs.

Availability and Purchasing Options

The Lisle 59000 tool is discontinued‚ making it challenging to find new. Used units are occasionally available on eBay or specialty automotive websites like 2040-parts.com.

Where to Buy the Lisle 59000 Tool

The Lisle 59000 Valve Guide Installation Tool is discontinued‚ but used or refurbished units can occasionally be found on eBay Motors or specialty automotive tool websites like 2040-parts.com. Additionally‚ some automotive forums or enthusiast communities may have members selling the tool. When purchasing‚ ensure the seller has a good rating and verify the tool’s condition. Local auto repair shops or machine shops might also have access to similar tools or alternatives for valve guide installation.

Discontinued Status and Alternatives

The Lisle 59000 Valve Guide Installation Tool is discontinued‚ making it challenging to find new units. While it is no longer in production‚ used tools occasionally surface on eBay Motors or specialty automotive websites. For those unable to locate the Lisle 59000‚ alternative valve guide installation tools are available from other manufacturers‚ offering similar functionality. These alternatives can be sourced through automotive supply stores‚ online marketplaces‚ or professional mechanic networks. Always verify compatibility with your specific engine before purchasing.

User Feedback and Reviews

Users praise the Lisle 59000 for its effectiveness and ease of use‚ noting it prevents common installation issues. However‚ its discontinuation has made it difficult to source.

Professional Mechanic Opinions

Professional mechanics highly regard the Lisle 59000 for its precision and effectiveness in valve guide installation‚ emphasizing its ability to prevent common alignment errors. Many consider it an essential tool for ensuring proper valve guide seating and reducing engine wear. However‚ some mechanics have noted that while the tool is excellent‚ it may be overhyped for certain applications‚ and its discontinuation has led to frustration among those who rely on it for consistent results.

DIY Enthusiast Experiences

DIY enthusiasts praise the Lisle 59000 for its ease of use and effectiveness in valve guide installation‚ allowing precise alignment without specialized machinery. Many report successful projects with minimal hassle‚ emphasizing its value for home garage repairs. However‚ some DIYers express frustration over the tool’s discontinued status‚ forcing them to seek alternatives or hunt for used units. Overall‚ it remains a recommended tool for those tackling engine rebuilds or repairs independently.

Troubleshooting Common Issues

Common issues with the Lisle 59000 include alignment problems and difficulty sourcing the discontinued tool. Consult installation guides or seek professional help for persistent challenges.

Resolving Installation Problems

Installation issues with the Lisle 59000 often stem from improper alignment or guide sizing. Ensure the tool is correctly seated and guides are lubricated. If guides stick‚ gently tap them into place. Consult the tool’s manual or online tutorials for detailed troubleshooting steps. If problems persist‚ consider consulting a professional mechanic or engine specialist for assistance. Proper technique and patience are key to successful valve guide installation.

Addressing Tool Malfunction

If the Lisle 59000 tool malfunctions‚ inspect for damage or wear. Clean the tool thoroughly and ensure proper lubrication of moving parts. Check alignment pins for bending or corrosion. If issues persist‚ verify proper usage techniques and consult the tool’s manual. For severe malfunctions‚ contact Lisle’s customer support or consider professional repair. Regular maintenance and proper storage can prevent future tool failure‚ ensuring reliable performance during valve guide installations.

The Lisle 59000 tool‚ though discontinued‚ remains a trusted solution for precise valve guide installations‚ offering reliability and efficiency for both professionals and DIY enthusiasts alike.

The Lisle 59000 Valve Guide Installation Tool is a testament to innovative engineering‚ offering precision and ease in valve guide installations. Despite its discontinued status‚ it remains a sought-after solution for professionals and DIY enthusiasts alike. Its ability to ensure proper alignment and seating of valve guides has made it a trusted choice‚ even as alternatives emerge. For those fortunate enough to acquire it‚ the tool continues to deliver reliable performance‚ solidifying its reputation as a valuable asset in engine repair.

Recommendations for Future Use

Given the Lisle 59000 tool’s discontinued status‚ users are advised to explore alternative tools or methods for valve guide installation. For those still using the tool‚ proper maintenance and adherence to manufacturer guidelines are crucial. DIY enthusiasts should consider consulting online tutorials or community forums for optimal results. Professionals may benefit from investing in modern‚ equivalent tools to ensure efficiency and precision in their workflows. Always prioritize tool condition and compatibility to achieve successful outcomes in engine repairs.