The Continental O-470 engine is a six-cylinder, horizontally opposed aircraft engine, widely used in general aviation for its reliability and efficiency. Regular overhauls ensure optimal performance.

1.1 Overview of the Continental O-470 Engine

The Continental O-470 is a six-cylinder, air-cooled, horizontally opposed aircraft engine, renowned for its reliability and efficiency. With a horsepower output ranging from 230 to 250, it is widely used in general aviation aircraft. Its compact design and smooth operation make it a popular choice for trainers and small aircraft. The engine features a robust construction, ensuring durability and performance under various flight conditions. Regular maintenance, as outlined in the overhaul manual, is critical to sustaining its operational integrity and safety standards.

1.2 Importance of Regular Overhaul

Regular overhaul of the Continental O-470 engine is critical to ensure safety, performance, and compliance with aviation standards. Over time, engine components experience wear and tear, which can lead to reduced efficiency and potential failures. A timely overhaul, as detailed in the manual, helps identify and replace worn parts, restoring the engine to its original specifications. This process prevents unexpected malfunctions, ensures optimal horsepower output, and maintains fuel efficiency. Compliance with overhaul schedules also extends the engine’s service life and reduces long-term operating costs, making it essential for both safety and economic reasons.

Understanding the O-470 Overhaul Manual

The O-470 Overhaul Manual provides detailed procedures, specifications, and guidelines for engine maintenance, ensuring compliance with safety standards and optimal performance. It is indispensable for engineers.

2.1 Structure and Content of the Manual

The O-470 Overhaul Manual is structured to guide engineers through the entire overhaul process. It includes sections on disassembly, inspection, repair, and reassembly, with detailed diagrams and torque specifications. The manual also covers essential tools and materials, ensuring compliance with safety standards. Additional resources, such as parts catalogs and troubleshooting guides, are provided to facilitate efficient and accurate maintenance. This comprehensive structure makes it an indispensable resource for anyone performing an O-470 engine overhaul.

2.2 Key Sections for Engineers and Mechanics

The manual emphasizes detailed repair procedures, torque specifications, and troubleshooting guides, which are crucial for engineers and mechanics. These sections ensure accurate disassembly, inspection, and reassembly, adhering to safety standards. The torque specifications are vital for proper engine assembly, preventing potential failures. Troubleshooting guides help diagnose issues efficiently, saving time and resources. Compliance with these guidelines ensures the engine operates at peak performance. These sections are essential for professionals conducting overhauls, providing clear, actionable instructions to maintain safety and efficiency.

Pre-Overhaul Checks and Preparation

Pre-overhaul checks involve inspecting engine components for wear or damage. Gathering specialized tools and materials ensures a smooth process, adhering to manual guidelines for safety and efficiency.

3.1 Inspection of Engine Components

The inspection of engine components is critical before starting an overhaul. Cylinders, piston rings, and valves must be checked for wear or damage. Crankshafts and camshafts are examined for scoring or excessive clearances. Bearings and seals are inspected for signs of fatigue or leakage. All components are compared against manufacturer specifications to determine if replacement is necessary. This step ensures compliance with safety standards and prevents costly surprises during reassembly. Proper documentation of findings guides the overhaul process, ensuring all issues are addressed effectively.

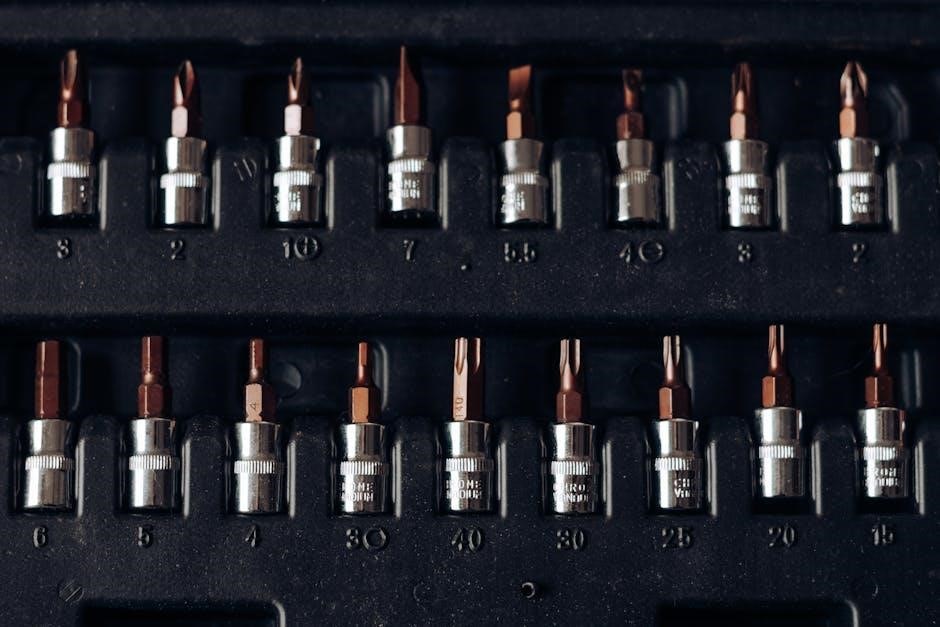

3.2 Tools and Materials Required

To perform an overhaul, specialized tools and materials are essential. These include piston ring compressors, bearing pullers, and torque wrenches. General tools like socket sets and wrenches are also necessary. Materials such as gaskets, seals, and lubricants must be sourced from approved suppliers. Adhesives and cleaning solvents are required for proper reassembly and testing. A detailed list of tools and materials is provided in the manual to ensure engineers are prepared. Proper equipment ensures accuracy and safety during the overhaul process, adhering to Continental’s specifications.

Step-by-Step Overhaul Procedures

The overhaul involves disassembling the engine, cleaning components, inspecting for wear, and reassembling with new parts. Detailed steps ensure precision and compliance with Continental’s standards.

4.1 Disassembly and Cleaning

Disassembly begins with removing the engine’s external components, such as the cowling and accessories, to access internal parts. The cylinders, pistons, and crankcase are carefully detached using specialized tools. Each component is inspected for wear or damage. Cleaning involves ultrasonic baths or chemical solvents to remove dirt and old lubricants. All parts are labeled and stored to ensure proper reassembly. The manual specifies torque values and reinstallation sequences to maintain engine integrity. Proper cleaning ensures accurate inspections and prevents contamination during reassembly. Safety protocols are emphasized to avoid damaging sensitive components.

4.2 Reassembly and Testing

Reassembly follows precise torque specifications and sequences outlined in the manual to ensure proper alignment and sealing. Specialized tools, like ring compressors, are used for delicate components. After reassembly, the engine undergoes rigorous testing, including oil pressure checks, compression tests, and magneto timing verification. A ground-run test is performed to validate performance, monitoring for leaks or unusual vibrations. Safety protocols are critical during this phase to ensure reliability and compliance with aviation standards. Any deviations from expected performance are addressed before final approval.

Post-Overhaul Testing and Validation

Post-overhaul testing ensures the engine meets performance and safety standards. Rigorous checks include engine runs, oil pressure tests, and magneto timing verification to confirm reliability and compliance.

5.1 Engine Performance Checks

Post-overhaul engine performance checks are critical to ensure the Continental O-470 engine operates within specified parameters. These checks include monitoring oil pressure, fuel flow, and RPM during ground runs. Mechanics use tachometers and fuel flow meters to verify performance. The engine must demonstrate smooth operation, consistent power output, and proper magneto timing. Cooling system efficiency and exhaust gas temperature are also evaluated. Any deviations from manufacturer specifications require immediate attention. These checks confirm the engine’s readiness for safe and efficient flight operations, ensuring compliance with performance and safety standards outlined in the overhaul manual.

5.2 Compliance with Safety Standards

Ensuring compliance with safety standards is paramount after the Continental O-470 engine overhaul. The manual emphasizes adherence to aviation regulations, such as FARs, to guarantee airworthiness. Rigorous inspections and tests must align with industry guidelines to verify the engine’s reliability. Proper documentation of all procedures is essential for traceability and regulatory approval. Mechanics must reference the latest service bulletins and technical updates to maintain compliance. By following these standards, the engine’s performance and safety are assured, minimizing risks during operation and ensuring continued reliability in demanding aviation environments.

Common Challenges and Solutions

Common challenges during the Continental O-470 overhaul include worn bearings and cylinders. Solutions involve precise measurements, replacing parts per manual specifications, and using approved tools for accuracy.

6.1 Troubleshooting During Overhaul

Troubleshooting during the Continental O-470 overhaul often involves identifying worn bearings, scoring on cylinder walls, or improper clearance issues. Mechanics should refer to the manual for torque specifications and alignment checks. Using precision tools ensures accurate measurements, preventing costly rework. If parts like piston rings or valve guides show excessive wear, immediate replacement is crucial. Additionally, verifying the condition of the crankcase and camshaft is essential to avoid future operational issues. Proper lubrication and adherence to overhaul procedures minimize risks of component failure during engine operation.

6.2 Optimizing Engine Performance

Optimizing the Continental O-470 engine performance involves proper reassembly, adherence to manual guidelines, and thorough testing. Ensuring all components are within specified tolerances minimizes wear and enhances efficiency. Proper lubrication and timing adjustments are critical. Post-overhaul, conduct ground runs to check for leaks or unusual noises. Regular maintenance, such as oil changes and filter inspections, sustains performance. Utilizing diagnostic tools to monitor compression and fuel flow helps identify potential issues early. By following these steps, the engine delivers reliable power and longevity, meeting safety and operational standards effectively.

Maintenance and Inspection After Overhaul

Regular inspections and routine maintenance ensure the Continental O-470 engine operates efficiently post-overhaul. Adherence to service manuals and timely replacements guarantee longevity and optimal performance.

7.1 Routine Maintenance Schedule

A well-structured maintenance schedule is crucial for the Continental O-470 engine. This includes regular oil changes, filter inspections, and spark plug replacements. Mechanics should follow the manual’s guidelines to ensure all tasks are performed at specified intervals. Additionally, visual inspections of engine components like cylinders and hoses are recommended to identify potential issues early. Adhering to this schedule helps maintain engine reliability, prevents unexpected failures, and extends service life. Proper documentation of each maintenance activity is also essential for tracking and future reference.

7.2 Extended Service Life Tips

To maximize the service life of the Continental O-470 engine, adhere to recommended maintenance practices and operational guidelines. Ensure proper cooling system performance to prevent overheating. Use high-quality fuel and lubricants to minimize wear. Regularly inspect and replace worn components before they cause further damage. Avoid operating the engine at extreme temperatures or under excessive stress. Store the engine properly during extended periods of inactivity, following the manual’s preservation procedures. By combining these practices with a thorough routine maintenance schedule, you can significantly extend the engine’s operational life and reliability.